RAXTiFY Color PPF

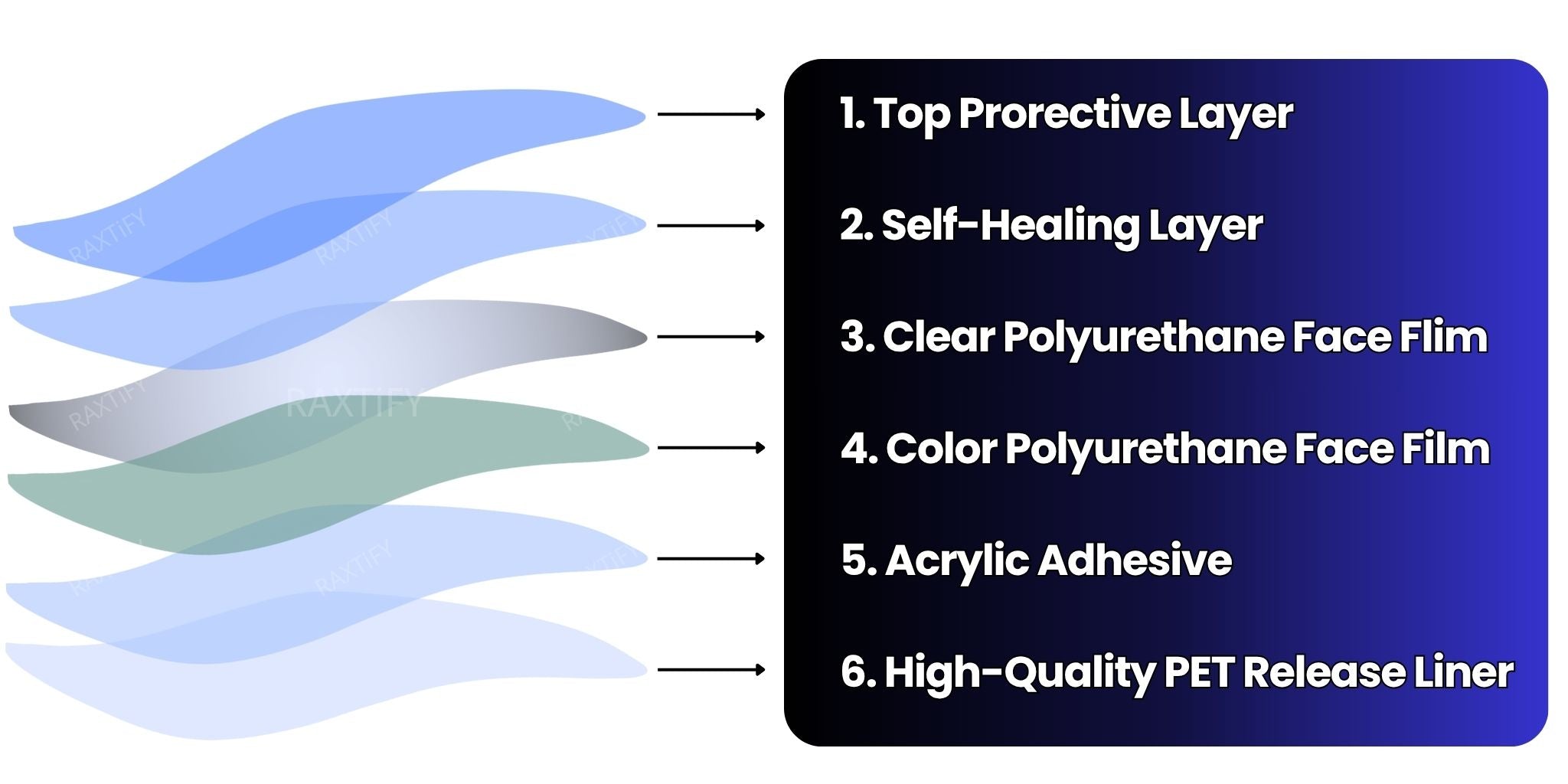

Structure

Why Choose RAXTiFY Color PPF?

Why Choose Ultra-Gloss Pearl White PPF?

Ultra-Gloss Pearl White Paint Protective Film (PPF) - Made from cutting-edge thermoplastic polyurethane (TPU), this innovative material sets new standards in the automotive protective film market.

1. Pearl White: The Colour of Elegance and Purity

Pearl white is more than just a color; it's an expression of sophistication and purity. This shade exudes timeless elegance, making it an excellent choice for you seeking a premium, high-end appearance. An ultra-gloss finish magnifies pearl white's natural beauty for maximum impact - creating a mirror-like shine on the road that attracts attention wherever you travel.

2. Unmatched Protection

- Superior Durability: Our TPU-based PPF offers superior resistance against scratches, stone chips, and other environmental hazards, ensuring your car remains in showroom condition.

- Self-Healing Properties: The advanced TPU material is designed to repair itself from minor scratches and swirl marks, maintaining a flawless finish.

- UV Protection: It provides excellent UV resistance, preventing your car’s paint from fading and keeping it looking vibrant for longer.

3. Aesthetic Enhancement

- Colour Transformation: Beyond protection, this film transforms the look of your car, giving it a luxurious and sophisticated appearance with the ultra-gloss pearl white finish.

- Customisable Finish: Whether you prefer a sleek, modern look or a classic, timeless style, the ultra-gloss finish complements any vehicle’s design, enhancing its natural curves and lines.

- Showroom Shine: The high-gloss finish provides a mirror-like shine that enhances the car’s overall appearance, making it stand out in any setting.

4. Investment in Quality

Ultra-Gloss Pearl White PPF may come at a higher price point, but it represents an invaluable long-term investment for maintaining and improving the appearance of your vehicle. Thanks to its durable properties and self-healing abilities, frequent touchups or repainting don't become necessary - saving both time and money in maintenance costs.

Key Features

- Longevity: Designed to last, this film provides years of reliable protection and maintains its glossy finish with proper care.

- Ease of Application: The film can be applied with minimal fuss, providing a smooth, seamless finish that enhances your car’s aesthetics.

- Market-Leading Technology: Utilizing the latest advancements in TPU technology, this PPF sets a new benchmark for quality and performance in the automotive industry.

Conclusion

When you seek original products for your car, the Ultra-Gloss Pearl White Paint Protective Film is the investment. It is distinguished not just by fantastic protection, lovely appearance (even under heavy use), and heavy-duty quality document formats. This PPF goes on and on With elegance and quality protection combined, Ultra-Gloss Pearl White PPF is the most beautiful protective film for cars anywhere.

Product Specifications

| Clear PPF | Specifications |

|---|---|

| Technology | High-grade TPU (Thermoplastic Polyurethane) |

| Total Thickness | 7.63mil |

| Top Coat Thickness | 0.31 mil |

| TPU Layer Thickness | 4.80 mil |

| Base Layer Thickness | 1.5 mil |

| Adhesive Thickness | 1.02 mil |

| Release Liner | PET |

| Top Coat | Ultra Gloss/Matte & Self-Healing |

| Adhesive Type | Removable & Reposition Acrylic |

| Width (Standard) | 5ft/ 60in/ 1.52m |

| Length (Standard) | 49ft/15m |

| Application | Wet Apply |

Techniocal Details

| Test | Data | Test Conditions |

|---|---|---|

| Hydrophobic | 40° | Angle contact |

| Self-Healing | 70 °C | Heat Gun |

| Anti-Permeation | Best | Permanent Marker |

| Anti-Yellowing ΔΕ | ≤2.5 | Q-UV, 1000hrs |

| Anti-Chipping | Best | SAE J400 |

| Tensile strength | ≥19(mpa) | GB/T 1040.1 |

| Holding Power(gf/inch) | 2275 | GB/T279224h |

| Initial Tack(gf/inch) | 1500 | GB/T2792 |

| Peel Adhesion | ≥16(N/25mm) | GB/T 2792 |

| Hardness | ≥90 | ISO0868/ASTM D-2240 |

| Tear Strength | 91.5KN/m | GB/T529 |

| Release Force(N/25mm) | 0.25 | paste on steel board, 90° 26'C and 60%, GB2792 |

| Elongation at Break | 340 | GB/T1040.1 |

| Coating Elongation at Break | 109 | GB/T1040 |

| Chemical Resistance | No Detrimental Effect | 1-hour diesel oil immersion, 4 hours antifreeze immersion |

| UV Resistance | 98% | / |

| Water Resistance | No Detrimental Effect | 120 hours immersion |

| Mud Resistance | No Detrimental Effect | 120 hours exposure |

| Salt Resistance | No Detrimental Effect | 120 hours exposure |

| Alkali Resistance (168H) | No abnormalities | 20% sodium hydroxide solution |

| Light Transmission | 89% | / |

| Aging Testing | 90°C and 7 days | No adhesive residue without heat |

| Application Temperature | +20°C to +30°C | / |

| Durability | 8-10years | / |

| Application Method | Wet Application | / |

| Gloss | ≥ 91% | 60° |

You Might Also Like

- Choosing a selection results in a full page refresh.

!