Video of Color Shift Lemon Peach Vinyl Wrap

Features:

- Unique lemon peach pattern

- High-quality and durable vinyl wrap

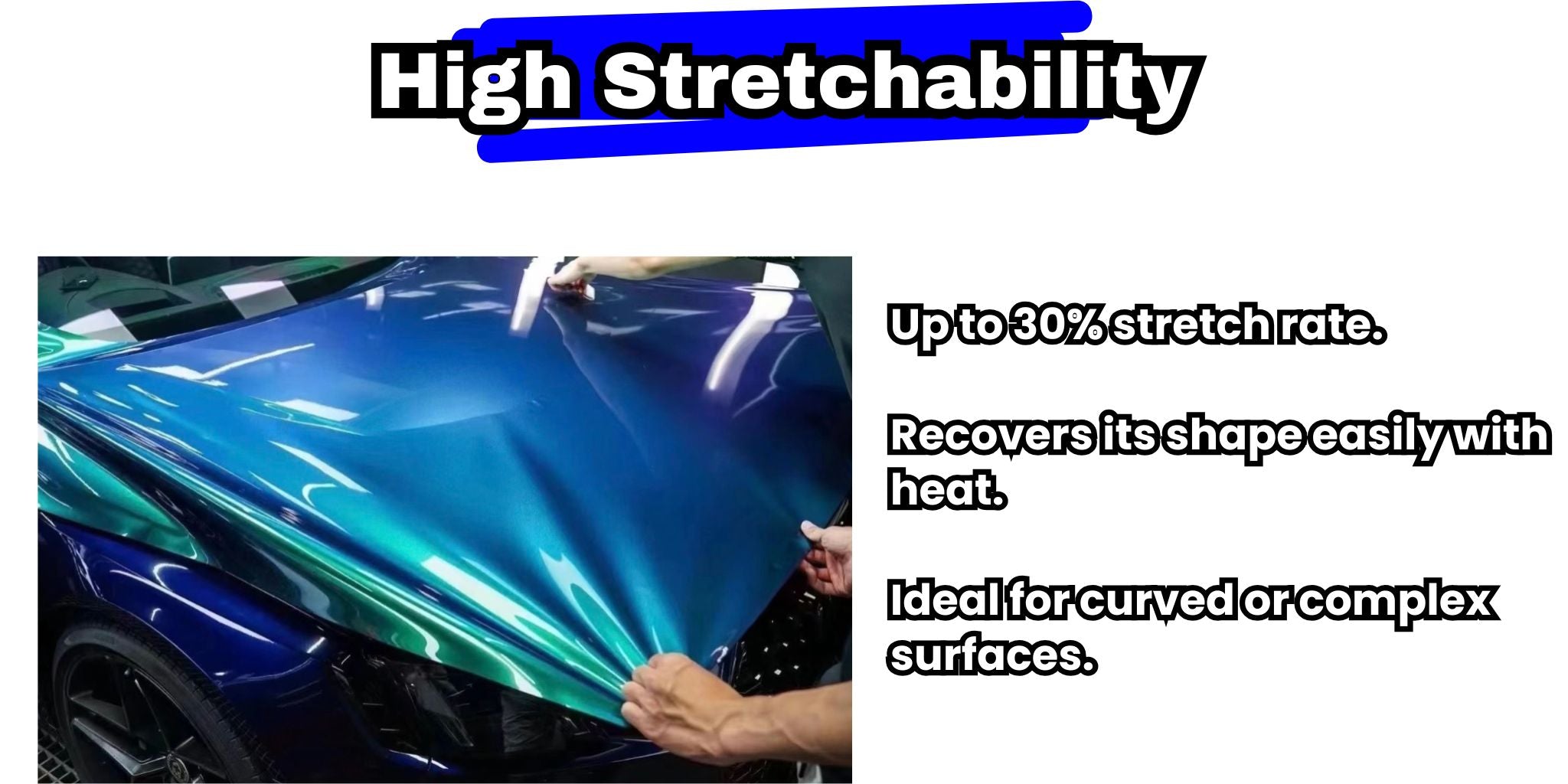

- Equipped with air-release channels for bubble-free application

- Easy to use: peel and stick

- UV resistant, ensuring years of fade-free use

- Durable, waterproof, and resistant to fading and wrinkling

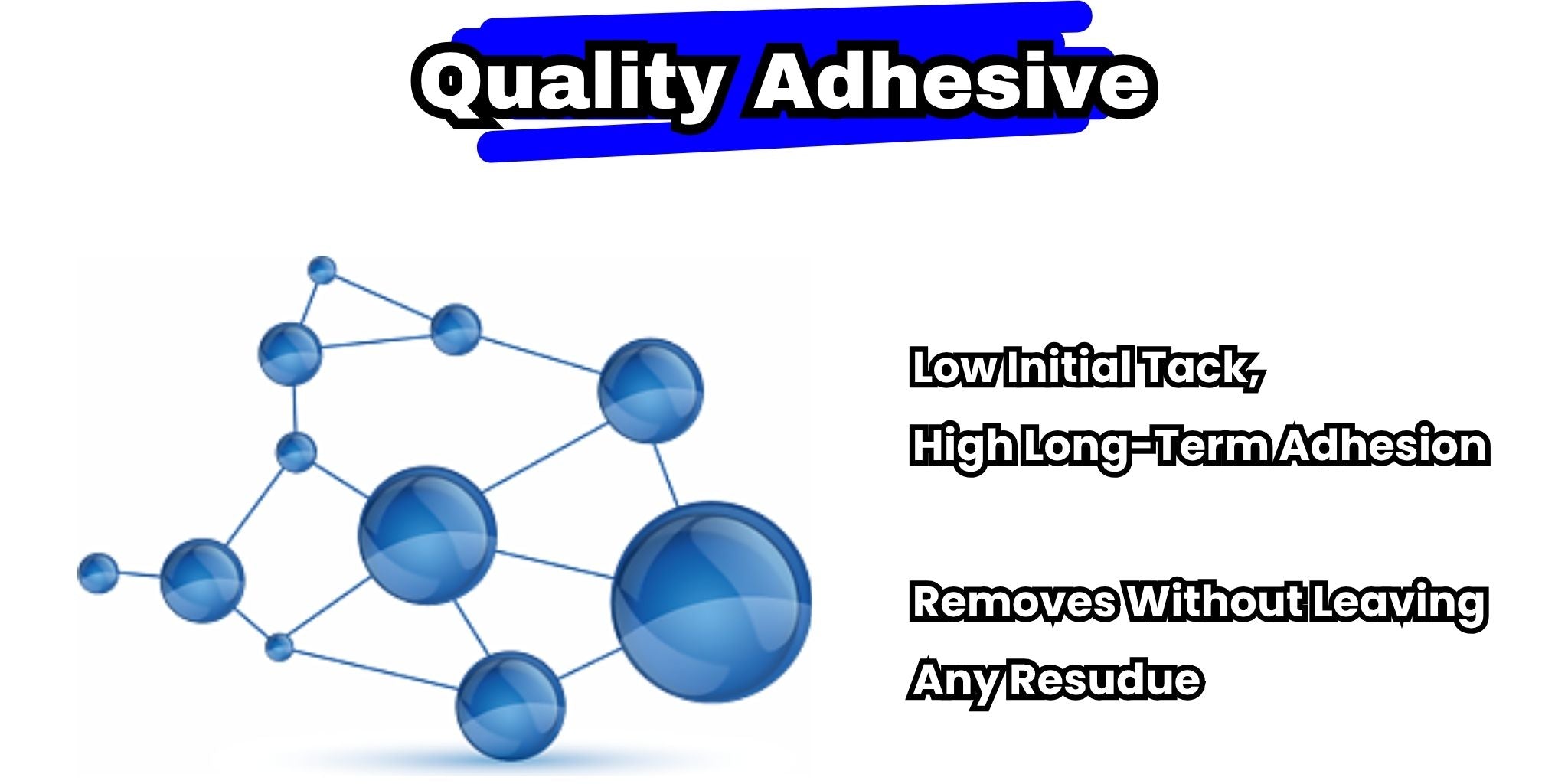

- Leaves no marks when removed

- Eco-friendly and non-toxic

- Suitable for car wraps, motorcycles, boats, bikes, and more

Specifications:

- Color: Lemon Peach (Yellow Pink)

- Finish: Color Shift

- Material: High-grade polymetric calendered vinyl film

- Lifespan: 2-3 years (with proper installation and maintenance)

- Recommended Uses: Automotive

- Shipping Time: Standard shipping: 7-12 days; Faster shipping: 3-5 days

- Sizes Available: 5ft x 3ft, 5ft x 10ft, 5ft x 16ft, 5ft x 33ft, 5ft x 49ft, 5ft x 59ft, 5ft x 69ft, 5ft x 75ft

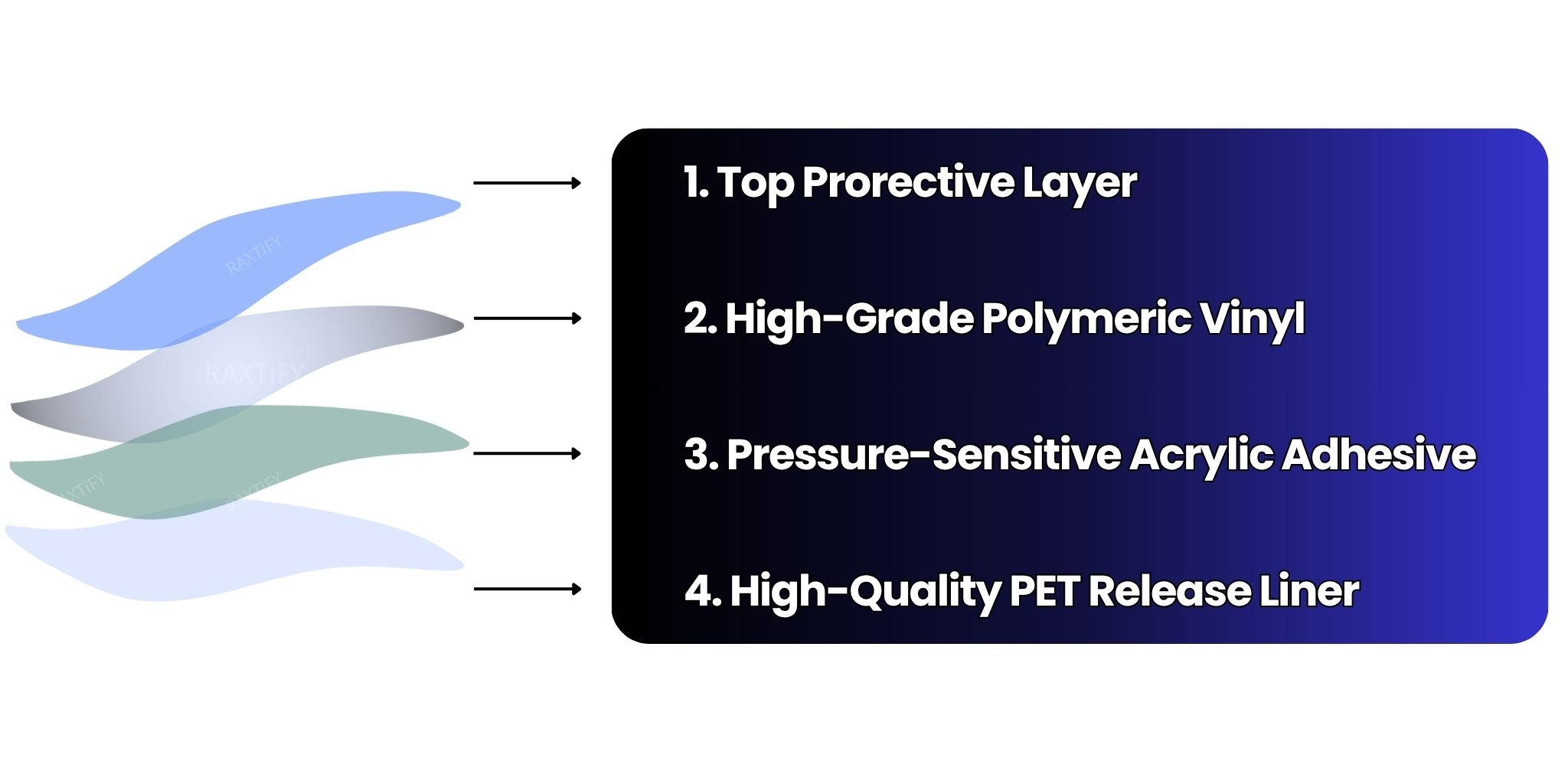

Structure

Our wrap films consist of 4 layers designed to ensure exceptional performance.

The first layer serves as a protective barrier for the underlying vinyl. Directly beneath, you'll find high-grade polymeric vinyl fortified with pressure-sensitive acrylic adhesive. Finally, a layer of top-tier 130um plastic liner adds an extra level of quality to our wrap films. This plastic liner ensures a smoother, super glossy, and lustrous finish

Product Specifications

| RAXTiFY VINYL | Specifications |

|---|---|

| Technology | High-grade Polymeric Calendared Vinyl Film with Air-Release Channels |

| Top Protective Liner | PET |

| Thickness (Face only) | 3.7mil-4.1mil |

| Thickness (Adhesive) | 1.6 mil (Removable Adhesive with air-release channels) |

| Glue | Solvent based adhesive, (Low-Medium Tack - Easy to reposition) |

| Release Liner | PET/Plastic |

| Width (Standard) | 5ft/ 60in/ 1.52m |

| Length (Standard) | 59ft/ 65yard/ 18m |

| Indoor Lifespan | 3 years when following rules of application and use |

| Outdoor Lifespan | 2 years when following rules of application and use (Except Chrome Wraps) |

Wrap Testing

| RAXTiFY VINYL | Testing Result |

|---|---|

| Dimensional Stability | Shrinkage less than 4% |

| Breaking Strength | 22.7 N/10mm |

| Release Force (N/25mm) | 0.13 (25℃ and 50%) |

| Initial Tack (g/25mm) | 1360 (26℃ and 64%, GB31125-2014) |

| Peel Strength (N/25mm) | 7.02 (25℃and 42%, GB/T2792-1998) |

| Holding Power (h) | 75.09 (25℃ and 50%, GB/T4851-1998) |

| Chemical Resistance | Resists Most Mild Acids, Mild Alkalis, and Salt |

| Aging Testing | No adhesive residue with heat under 65°C after 7 days |

| Aging Test 2 | No adhesive residue without heat under 65°C after 10 days |

| Storing Period | 2 years if stored in +10°С to +20°С for optimal quality, relative humidity 50%, in original package, away from direct sunlight, clean and dry place |

Application

| RAXTiFY VINYL | Application Advices |

|---|---|

| Recommended Tools | Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, IRR heater |

| Application | Standard methods for calendared films. No overstretching and overheating and Post heating is necessary. |

| Post-heating Temperature | 110°C flat surfaces, 130°C curves, and overlaps (Except Chrome Wraps) |

| Recommended Installation Area Temperature | 70 F - 80 F (24 C - 26.5 C) |

| Directional | All vinyl wraps are recommended to be installed directionally |

| Application Method | Dry Application (Except PPF) |

| Aftercare | PH neutral, Avoid wax or solvents |

Need A Sample First?

Got your eyes on a color but not sure if it's the one? Get a FREE small sample first!

You Might Also Like

- Choosing a selection results in a full page refresh.

!