Video

Color Shift Neon Sky Blue On Different Vehicles

Color Shift Neon Sky Blue on Charger

Color Shift Neon Sky Blue on Nissan

Toyota Supra Color Shift Neon Sky Blue Vinyl Wrap

Color Shift Neon Sky Blue on BMW

Product Description

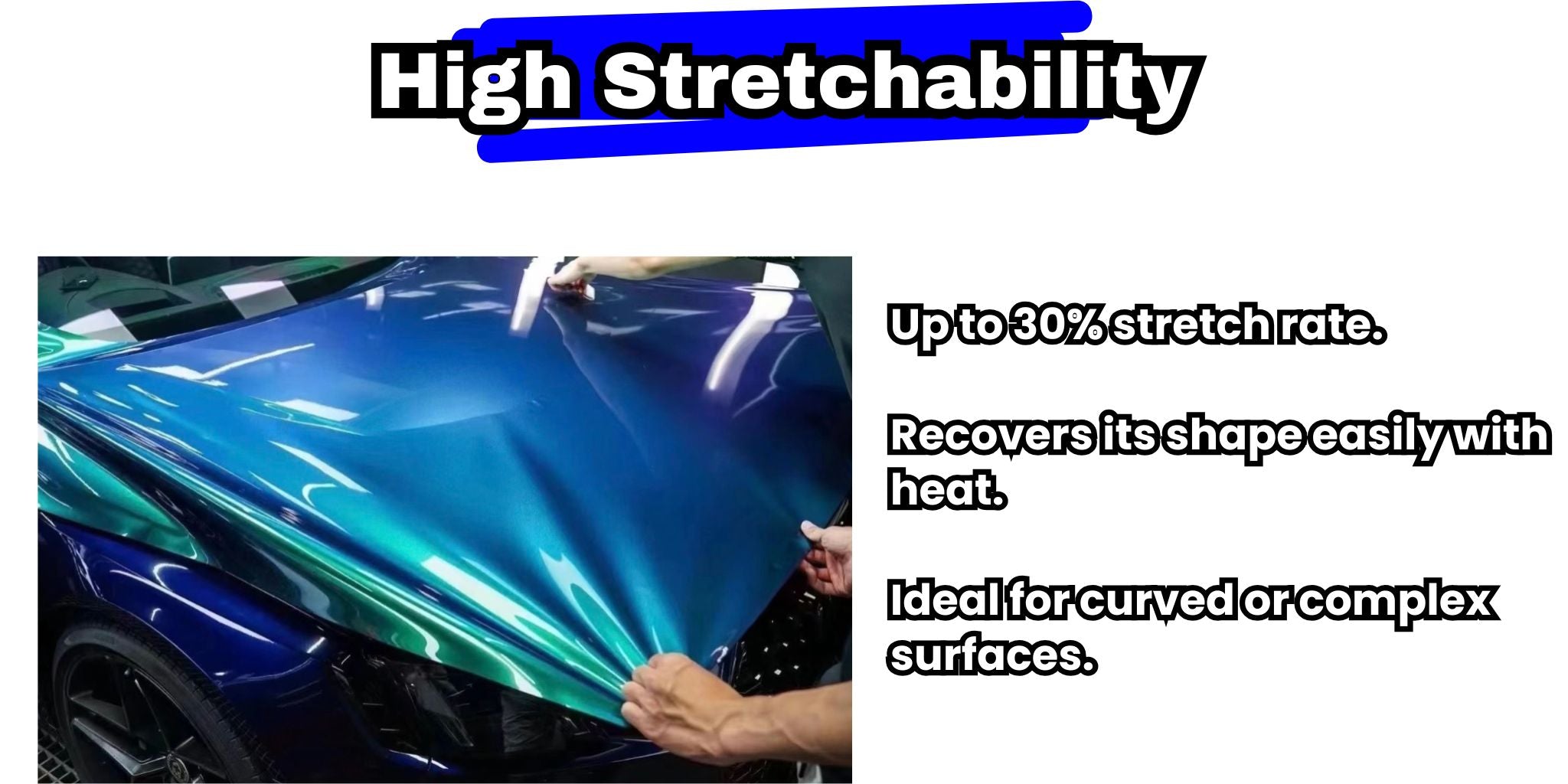

Color Shift Neon Sky Blue Vinyl Wrap Outfit your ride or your work and get a wild appearance of the attention getting variety of color in the light and dark. It is a good quality vinyl that is very sturdy and user friendly (when it comes to installation a smooth and neat bubble free job is accomplished easily). Ideal selection to implement by such professionals who are interested in using it to create a bright and broad look and provide acceptable coverage against scratches and weather.

Stunning Visual Appeal

The neon sky blue color is energy giving with variations at various angles based on lighting. When in full sun it shines like electrifying blue. There is a dramatic and interesting effect as the tones are deepening in the evening. Such is a dynamic nature that would cost you seeing your vehicle on the road the same twice.

Features of the Color Shift Neon Sky Blue Vinyl Wrap

Vivid Neon Hue with Color Shift Effect

The novel approach where neon makes the brightness combine with changing tones makes it a wrap that appears as a living one. It offers a vibrant yet very refined play of colors, light blue of heavens above to faint traces of aqua.

Glossy, Smooth Surface

The high gloss also boosts the shine of the color and provides your car with a super mirror appearance. This smooth vinyl wrap creates a touch of luxuriousness to give your car a better appearance. .

Durable and Protective

The wrap, which is made of high Quality film, provides a protective covering to your existing paint on your car. It keeps your car clean and bright as it is resistant to minor scratches, dust, and hits by UV-rays.

Easy to Install and Remove

This vinyl wrap is valuable because with air-release technology, it is definitely not going to get into any bubbles when making the installation. At the change of time, you can easily remove the film without messing up the paint of your car.

Versatile Application

The wrap can cover full-body cars, half wraps, or even smaller models such as interior trims, bikes and more. Its versatility makes it popular with professionals and also the DIYer.

Specifications:

- Color: Neon Sky Blue

- Finish: Color Shift

- Material: High-grade polymetric calendered vinyl film

- Lifespan: 2-3 years with proper installation and maintenance

- Recommended Uses: Automotive

- Shipping Time: Standard shipping: 7-12 business days; Faster shipping: 3-5 business days

- Sizes Available: 5ft x 3ft, 5ft x 10ft, 5ft x 16ft, 5ft x 33ft, 5ft x 49ft, 5ft x 59ft, 5ft x 69ft, 5ft x 75ft

Final Impression

And in case you are looking at wrap that is pretty futuristic but not too overly odd, you could turn to the Color Shift Neon Sky Blue Vinyl Wrap. It provides unparalleled picture-dimension, great durability as well as flexibility to upgrade your car without patronage of permanent contract.

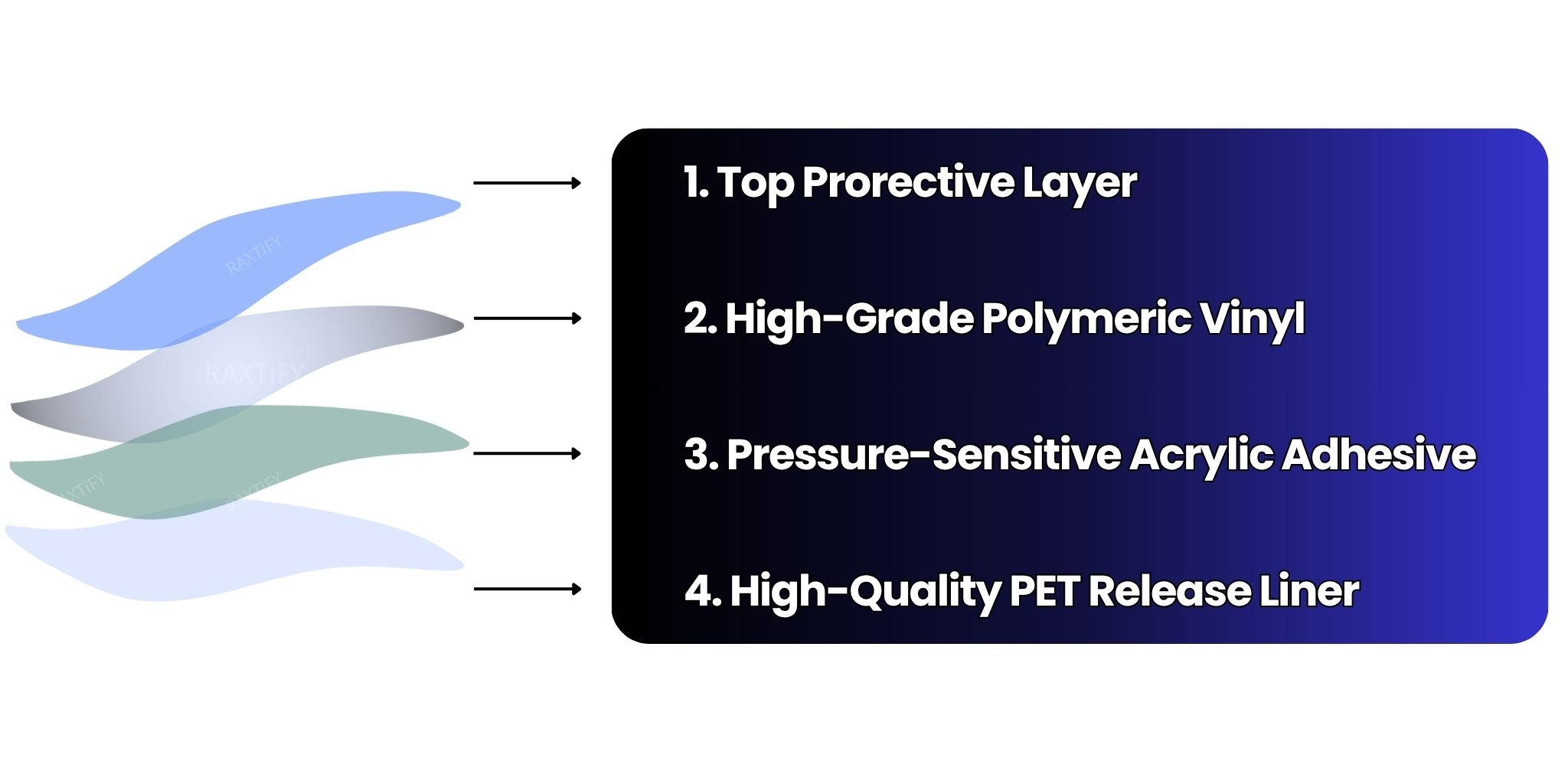

Structure

Our wrap films consist of 4 layers designed to ensure exceptional performance.

The first layer serves as a protective barrier for the underlying vinyl. Directly beneath, you'll find high-grade polymeric vinyl fortified with pressure-sensitive acrylic adhesive. Finally, a layer of top-tier 130um plastic liner adds an extra level of quality to our wrap films. This plastic liner ensures a smoother, super glossy, and lustrous finish

Product Specifications

| RAXTiFY VINYL | Specifications |

|---|---|

| Technology | High-grade Polymeric Calendared Vinyl Film with Air-Release Channels |

| Top Protective Liner | PET |

| Thickness (Face only) | 3.7mil-4.1mil |

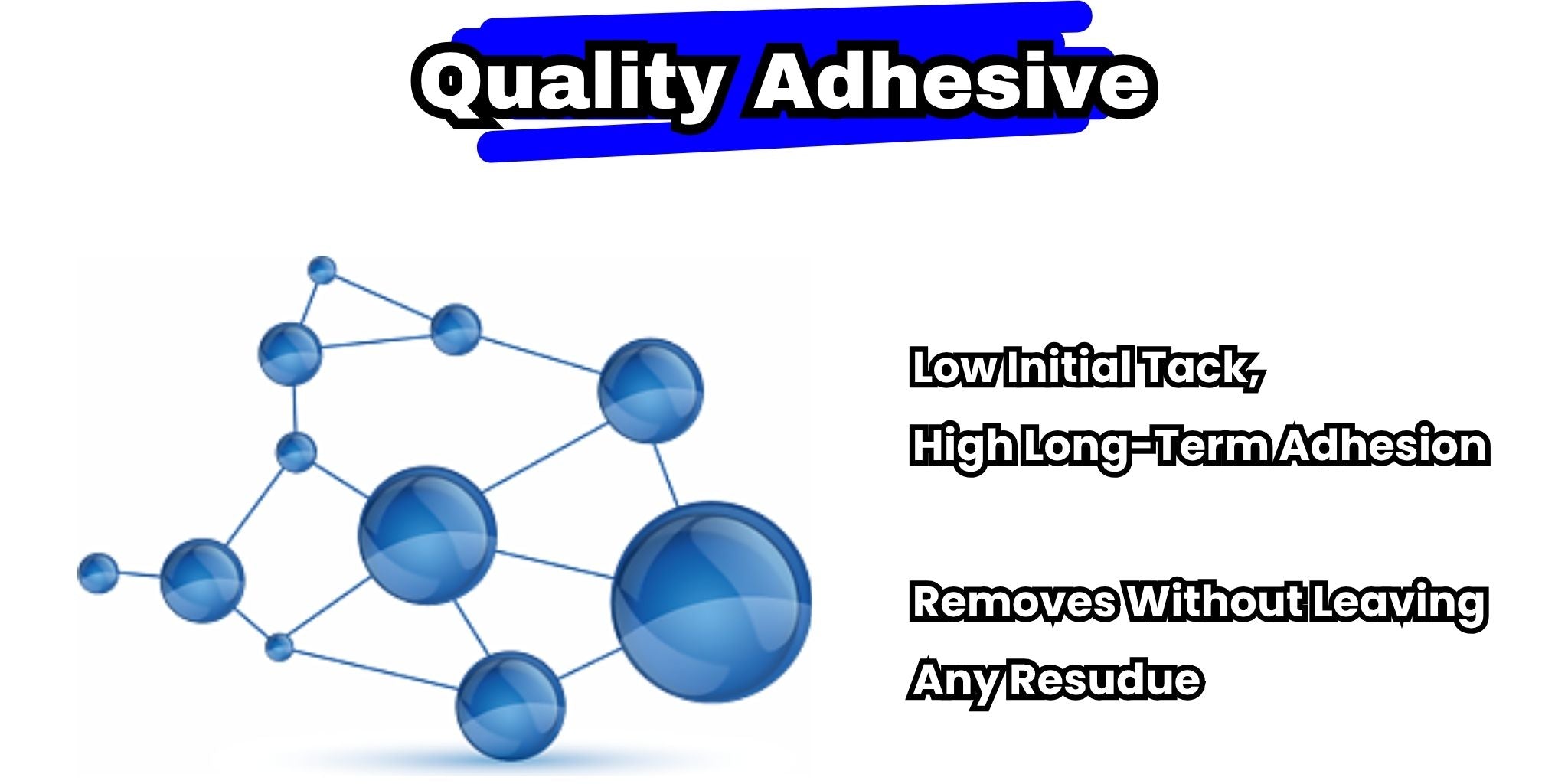

| Thickness (Adhesive) | 1.6 mil (Removable Adhesive with air-release channels) |

| Glue | Solvent based adhesive, (Low-Medium Tack - Easy to reposition) |

| Release Liner | PET/Plastic |

| Width (Standard) | 5ft/ 60in/ 1.52m |

| Length (Standard) | 59ft/ 65yard/ 18m |

| Indoor Lifespan | 3 years when following rules of application and use |

| Outdoor Lifespan | 2 years when following rules of application and use (Except Chrome Wraps) |

Wrap Testing

| RAXTiFY VINYL | Testing Result |

|---|---|

| Dimensional Stability | Shrinkage less than 4% |

| Breaking Strength | 22.7 N/10mm |

| Release Force (N/25mm) | 0.13 (25℃ and 50%) |

| Initial Tack (g/25mm) | 1360 (26℃ and 64%, GB31125-2014) |

| Peel Strength (N/25mm) | 7.02 (25℃and 42%, GB/T2792-1998) |

| Holding Power (h) | 75.09 (25℃ and 50%, GB/T4851-1998) |

| Chemical Resistance | Resists Most Mild Acids, Mild Alkalis, and Salt |

| Aging Testing | No adhesive residue with heat under 65°C after 7 days |

| Aging Test 2 | No adhesive residue without heat under 65°C after 10 days |

| Storing Period | 2 years if stored in +10°С to +20°С for optimal quality, relative humidity 50%, in original package, away from direct sunlight, clean and dry place |

Application

| RAXTiFY VINYL | Application Advices |

|---|---|

| Recommended Tools | Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, IRR heater |

| Application | Standard methods for calendared films. No overstretching and overheating and Post heating is necessary. |

| Post-heating Temperature | 110°C flat surfaces, 130°C curves, and overlaps (Except Chrome Wraps) |

| Recommended Installation Area Temperature | 70 F - 80 F (24 C - 26.5 C) |

| Directional | All vinyl wraps are recommended to be installed directionally |

| Application Method | Dry Application (Except PPF) |

| Aftercare | PH neutral, Avoid wax or solvents |

Need A Sample First?

Got your eyes on a color but not sure if it's the one? Get a FREE small sample first!

You Might Also Like

- Choosing a selection results in a full page refresh.

!