The Ultimate Guide to Evaluating Car Wrap Quality

Car wraps offer an enticing blend of style and protection for your vehicle. To ensure you're getting the best out of your investment, it's essential to assess the quality of the car wrap at three critical parts: during production, upon delivery, and after installation.

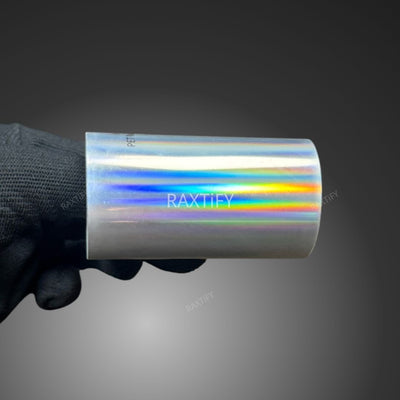

Raxtify is committed to excellence, employing rigorous tests to uphold the highest standards for our car wrap films. In this blog, we'll dive into how we test car wrap quality and some suggestion for you to identify a vinyl wrap.

How To Check Vinyl Wrap Quality Before Delivery

At Raxtify, every step of our production process is geared towards delivering excellence. Our rigorous testing methods, encompassing adhesion, stretchability, UV resistance, chemical resilience, durability, and aging, ensure that our car wrap films surpass the highest standards of quality, durability, and performance. With Raxtify car wrap films, you can be confident that you're investing in a product that not only enhances your vehicle's appearance but also provides long-lasting protection.

1. Car Wrap- Adhesion Test

Ensuring Firm Adhesion: We rigorously assess the adhesion of our car wrap film on various surfaces, including painted exteriors and glass windows. Our initial tack/g/25mm, evaluated using the GB31125-2014 test method, stands at an impressive 1360 under 26℃ and 64% humidity.

Controlled Release: Our car wrap films are designed to stay put, with a release force of just 0.12 under 25℃ and 50%, as per GB31125-2014 standards.

2. Car Wrap- Stretch Test

Perfect Conformity: We understand the importance of seamless conformity to a vehicle's curves and edges. Through comprehensive stretch tests, we ensure that our car wrap film stretches without tearing or cracking.

Peel Strength and Holding Power: Our films exhibit exceptional peel strength of 7 under 25℃ and 42%, according to GB/T2792-1998. Additionally, they offer a remarkable holding power of 72 under 25℃ and 50%, adhering to GB/T4851-1998 standards.

3. Car Wrap- UV Resistance Test

Battling UV Exposure: Our car wrap films are designed to defy the harsh impact of UV rays. Through extended exposure to UV light, we test their resistance to fading and discoloration, ensuring a lasting vibrant appearance.

4. Car Wrap- Chemical Resistance Test

Our car wrap films are exposed to various chemicals, including gasoline and oil, to validate their resilience. This rigorous test ensures that our films maintain their quality and appearance even when faced with challenging substances.

5. Car Wrap- Durability Test

To emulate real-world scenarios, we subject our car wrap films to extreme temperatures and moisture. This durability test gauges their performance under challenging environments.

Long Lifespan: Raxtify's car wrap films are built to last, with an estimated lifespan of approximately 2 years when stored in ideal conditions – between +10°C and +20°C, with a relative humidity of 50%. Stored in their original package in a clean, dry place away from direct sunlight, our films stand the test of time.

6. Aging Testing: Leaving No Residue Behind

No Residue Under Heat: Our films undergo an aging test at 65°C for 7 days, ensuring that they leave no adhesive residue, even under extreme conditions.

No Residue Without Heat: An additional test sees our films evaluated under the same conditions, albeit without heat exposure for 10 days, further attesting to their quality.

Car Wrap Delivery Inspection

Upon receiving the vinyl car wrap, here's how we further assess their quality:

1. Visual Inspection-The First Impression Matters

Begin by conducting a thorough visual inspection of the car wrap. Look for any bubbles, wrinkles, scratches, or other irregularities. A premium car wrap should smoothly adhere to the vehicle's surface without evident flaws.

2. Color and Gloss Consistency

Check if the color and gloss of the car wrap align with your expectations. High-quality wraps should match your vehicle's paint color and exhibit a similar level of shine.

3. Brand and Certification

The hallmark of quality is the brand's reputation and certifications. Opt for renowned brands with manufacturer logos and certifications on the wrap. This guarantees authenticity and superior quality.

4. Professional Installation

The expertise behind installation is crucial. Seek professional automotive wrap installation shops with experience and skills to ensure the wrap is correctly applied to the vehicle's body, guaranteeing optimal appearance and protective effects.

5. Customer Reviews

Before purchasing a car wrap, explore feedback from other vehicle owners. Learning from their experiences and insights can assist you in selecting the ideal wrap for your vehicle.

Post Installation - Achieving Flawless Perfection

After customers have applied the car wrap, here are some additional inspection points to ensure the quality and effectiveness of the wrap are at their best.

1. Check for Beveled Edges and Sharp Corners

Examine if there are any beveled edges or sharp corners around the wrap. These areas might affect both the adhesion and appearance of the wrap.

2. Inspect Tight Adhesion

Carefully examine whether the wrap adheres tightly to the surface of the vehicle. Ensure there are no areas with looseness or wrinkling.

3. Look for Any Omissions or Oversights

Inspect every section of the wrap, including corners and curves of the vehicle. Make sure there are no missed areas or sections that haven't adhered completely.

4. Check for Debris or Dust

Observe if there are any foreign particles, dust, or air bubbles underneath the wrap. These elements could impact the appearance and adhesion of the wrap.

5. Test the Wrap's Durability

Gently press different parts of the wrap with your finger or fingernail and observe the reaction. A high-quality wrap should exhibit some elasticity and not easily get damaged or deformed under slight pressure.

6. Inspect for Any Color or Texture Mismatch

Examine the color and texture of the wrap carefully under various lighting conditions. Ensure it maintains consistency with the original vehicle paint in different circumstances.

FAQ

Q1: How can I ensure the quality of a car wrap?

A1: Ensuring car wrap quality involves choosing reputable brands, inspecting certifications, and examining the wrap's adhesion, stretchability, UV resistance, and chemical resilience.

Q2: What tests are conducted to evaluate car wrap quality?

A2: Car wraps undergo adhesion tests, stretch tests, UV resistance tests, chemical resistance tests, durability tests, and aging tests to assess their performance under different conditions.

Q3: Why is adhesion important in car wraps?

A3: Adhesion ensures the wrap stays securely attached to the vehicle's surface. It's crucial for longevity, appearance, and protection against elements.

Q4: How do I choose the right car wrap brand?

A4: Opt for renowned brands with certifications and positive customer reviews. Check for manufacturer logos and certifications on the wrap to confirm authenticity and quality.

Q5: How do I check the quality of a car wrap after installation?

A5: After installation, inspect for beveled edges, tight adhesion, no omissions, no debris, and check if the wrap reacts well to light pressure.

Q6: What factors affect the lifespan of a car wrap?

A6: Factors include proper storage, UV exposure, environmental conditions, and maintenance. Following care guidelines can help extend the wrap's lifespan.

Q7: Can I clean a car wrap just like regular paint?

A7: While car wraps are durable, it's recommended to use gentle cleaning methods and avoid harsh chemicals to preserve their quality.

Final Words

Choosing and evaluating car wraps requires attention to essential aspects. Opt for reputable brands with certifications to ensure authenticity. Rigorous testing, including adhesion, stretch, UV resistance, and chemical resilience tests, guarantees optimal wrap performance. Professional installation minimizes imperfections and maximizes appearance.

Post-installation, regular inspections for beveled edges, tight adhesion, and color matching maintain the wrap's quality. Proper maintenance, following manufacturer guidelines, sustains the wrap's longevity and appearance.

In summary, informed decisions, thorough testing, professional installation, careful inspection, and diligent maintenance are the pillars of selecting a high-quality car wrap. Elevate your vehicle's aesthetics and protection by embracing the principles of quality assessment outlined in this guide.

Related Resources:

The Pros and Cons of Car Wrapping Vs. Painting

How Much Does It Cost To Vinyl Wrap A Car