Video | Color Shift Pearl Racing Tiffany Vinyl Wrap

Color Shift Pearl Racing Tiffany Vinyl Wrap on Different Vehicles

1. Color Shift Pearl Racing Tiffany Vinyl Wrap on Honda

2. Color Shift Pearl Racing Tiffany Vinyl Wrap on BMW

3. Color Shift Pearl Racing Tiffany Vinyl Wrap on Charger

Description of Color Shift Pearl Racing Tiffany Vinyl Wrap

Color Shift Pearl Racing Tiffany Vinyl Wrap uniquely changes its color to brighten with any light source. The color shift wrap displays a flowing color transition from soft pearl blue to signature Tiffany green tones as it changes with every streetlight and sunlight direction. This fresh and luxurious automotive appearance emerges because of the high-gloss pearlescent finish which makes your car transform into a moving piece of art.

Your car gets a contemporary look with special touches thanks to the style that changes color and highlights under city lights and in the dark. You'll seize passersby's views regardless of motion through city streets or when your car stands at a gathering due to its refined yet eye-catching color transitions.

A Color Shift Pearl Racing Tiffany Vinyl Wrap applied to Tesla Model 3 models and Porsche Panamera models alongside BMW M4 vehicles with sporty characteristics creates a regal final appearance for these premium vehicles.

The shiny gloss finish adds to their sleek lines to make sure they look elegant and also have a strong performance focus.What makes this vinyl wrap unique and stylish is the flow between Tiffany green and pearl racing blue. Driving will be more than transportation because it will create a distinctive visual appearance.

The installation of this wrap protects your vehicle against UV rays as well as minor scratches and bird droppings and tree sap. Through this protective layer your factory paint maintains its structural quality thus delivering a showroom-new appearance for numerous years. The vehicle’s surface keeps it shining with gloss under the sun and during evening mists.

A gentle hand dry after using mild automotive shampoo helps keep your wrap bright with its shimmering appearance. Your paintwork and vehicle wrap will last longer when you avoid both high-pressure hoses and aggressive blowers at automatic car washes.

Additional Highlights:

- Premium quality vinyl wrap with exceptional color clarity

- Ideal for both professional installers and DIY enthusiasts

- Simple peel-and-stick application process for hassle-free installation

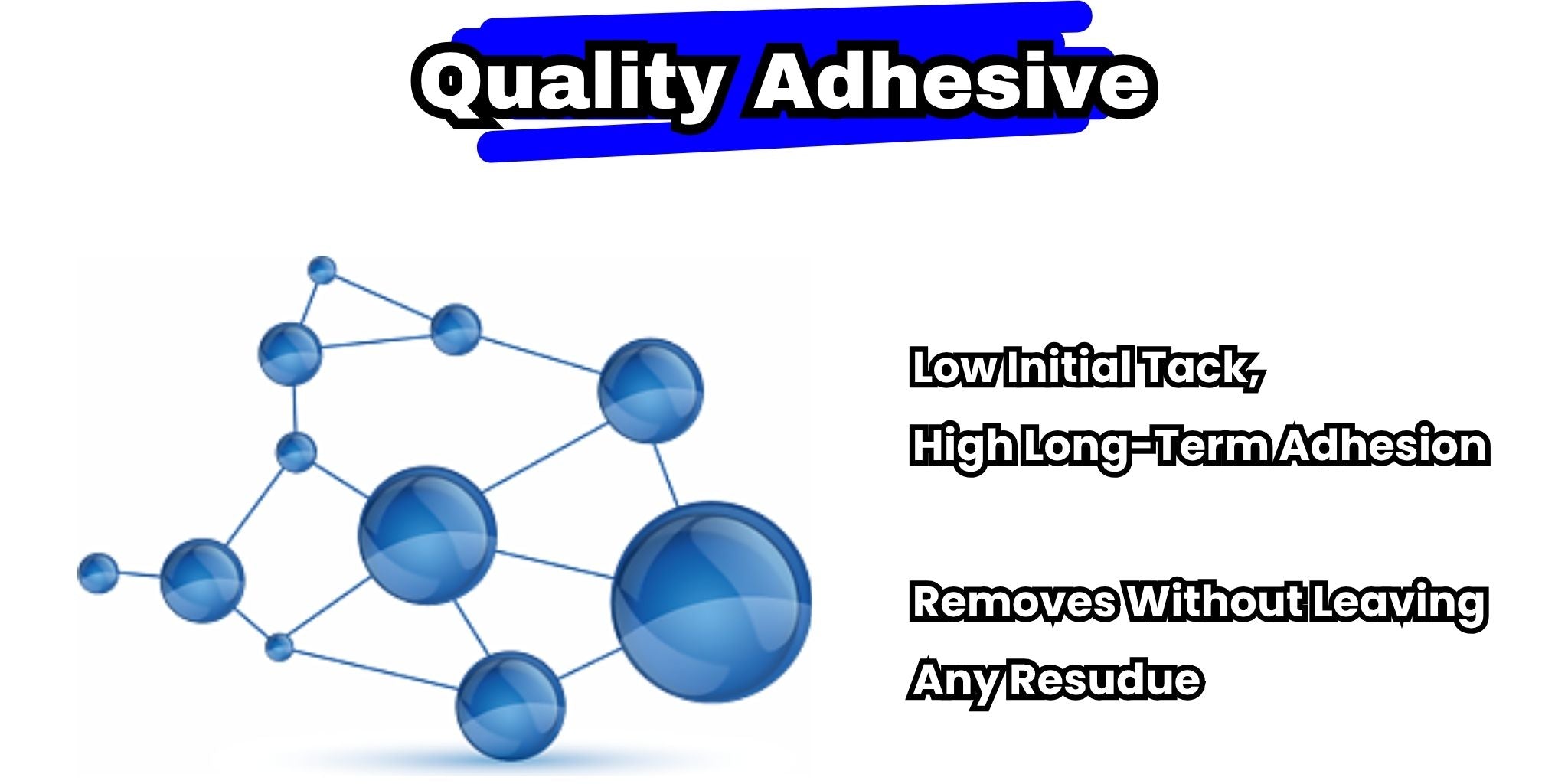

- Leaves no residue or damage upon removal

- Waterproof and resistant to fading, peeling, and wrinkling

- UV-resistant for long-lasting color retention.

Specifications:

- Color: Pearl Racing Tiffany

- Finish: Color Shift

- Material: High-grade polymetric calendered vinyl film

- Lifespan: 2-3 years (with proper installation and maintenance)

- Recommended Uses: Automotive

- Shipping Time: Standard shipping: 7-12 days; Faster shipping: 3-5 days

- Sizes Available: 5ft x 3ft, 5ft x 10ft, 5ft x 16ft, 5ft x 33ft, 5ft x 49ft, 5ft x 59ft, 5ft x 69ft, 5ft x 75ft

Things You Should Know

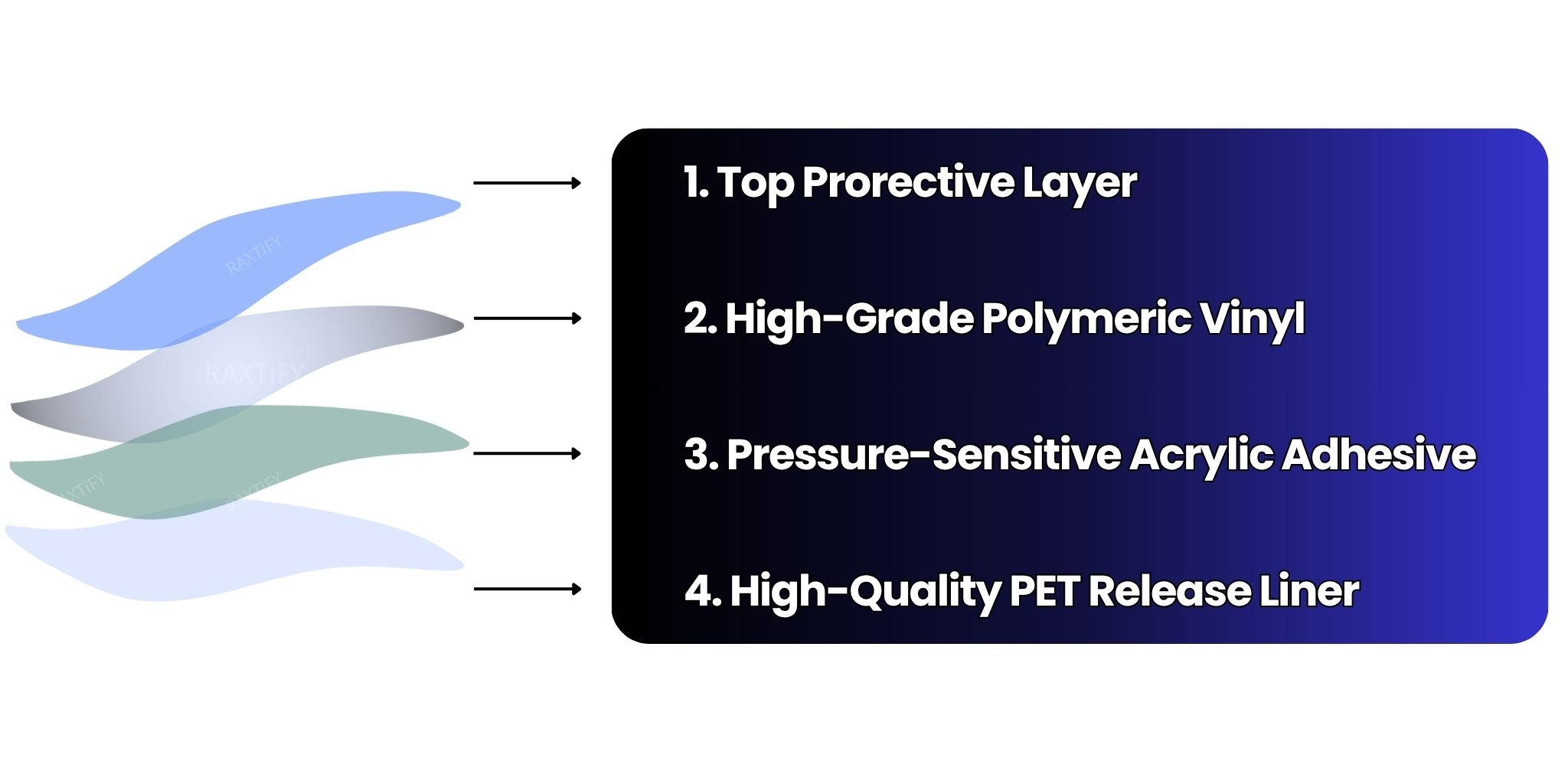

Structure

Our wrap films consist of 4 layers designed to ensure exceptional performance.

The first layer serves as a protective barrier for the underlying vinyl. Directly beneath, you'll find high-grade polymeric vinyl fortified with pressure-sensitive acrylic adhesive. Finally, a layer of top-tier 130um plastic liner adds an extra level of quality to our wrap films. This plastic liner ensures a smoother, super glossy, and lustrous finish

Product Specifications

| RAXTiFY VINYL | Specifications |

|---|---|

| Technology | High-grade Polymeric Calendared Vinyl Film with Air-Release Channels |

| Top Protective Liner | PET |

| Thickness (Face only) | 3.7mil-4.1mil |

| Thickness (Adhesive) | 1.6 mil (Removable Adhesive with air-release channels) |

| Glue | Solvent based adhesive, (Low-Medium Tack - Easy to reposition) |

| Release Liner | PET/Plastic |

| Width (Standard) | 5ft/ 60in/ 1.52m |

| Length (Standard) | 59ft/ 65yard/ 18m |

| Indoor Lifespan | 3 years when following rules of application and use |

| Outdoor Lifespan | 2 years when following rules of application and use (Except Chrome Wraps) |

Wrap Testing

| RAXTiFY VINYL | Testing Result |

|---|---|

| Dimensional Stability | Shrinkage less than 4% |

| Breaking Strength | 22.7 N/10mm |

| Release Force (N/25mm) | 0.13 (25℃ and 50%) |

| Initial Tack (g/25mm) | 1360 (26℃ and 64%, GB31125-2014) |

| Peel Strength (N/25mm) | 7.02 (25℃and 42%, GB/T2792-1998) |

| Holding Power (h) | 75.09 (25℃ and 50%, GB/T4851-1998) |

| Chemical Resistance | Resists Most Mild Acids, Mild Alkalis, and Salt |

| Aging Testing | No adhesive residue with heat under 65°C after 7 days |

| Aging Test 2 | No adhesive residue without heat under 65°C after 10 days |

| Storing Period | 2 years if stored in +10°С to +20°С for optimal quality, relative humidity 50%, in original package, away from direct sunlight, clean and dry place |

Application

| RAXTiFY VINYL | Application Advices |

|---|---|

| Recommended Tools | Squeegee, buffer, knife, masking tape, heat gun, magnets, gloves, IRR thermometer, IRR heater |

| Application | Standard methods for calendared films. No overstretching and overheating and Post heating is necessary. |

| Post-heating Temperature | 110°C flat surfaces, 130°C curves, and overlaps (Except Chrome Wraps) |

| Recommended Installation Area Temperature | 70 F - 80 F (24 C - 26.5 C) |

| Directional | All vinyl wraps are recommended to be installed directionally |

| Application Method | Dry Application (Except PPF) |

| Aftercare | PH neutral, Avoid wax or solvents |

Need A Sample First?

Got your eyes on a color but not sure if it's the one? Get a FREE small sample first!

You Might Also Like

- Choosing a selection results in a full page refresh.

!